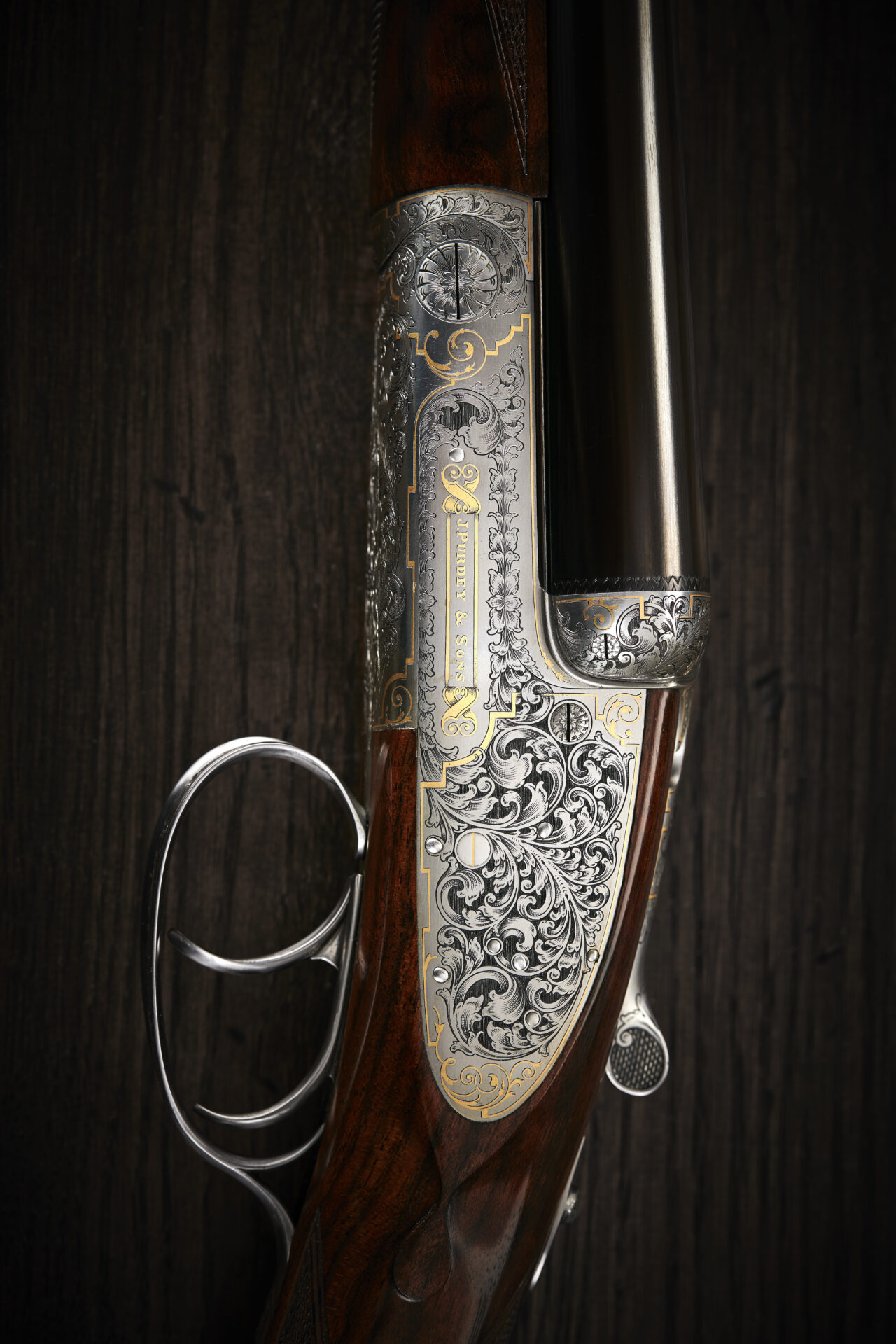

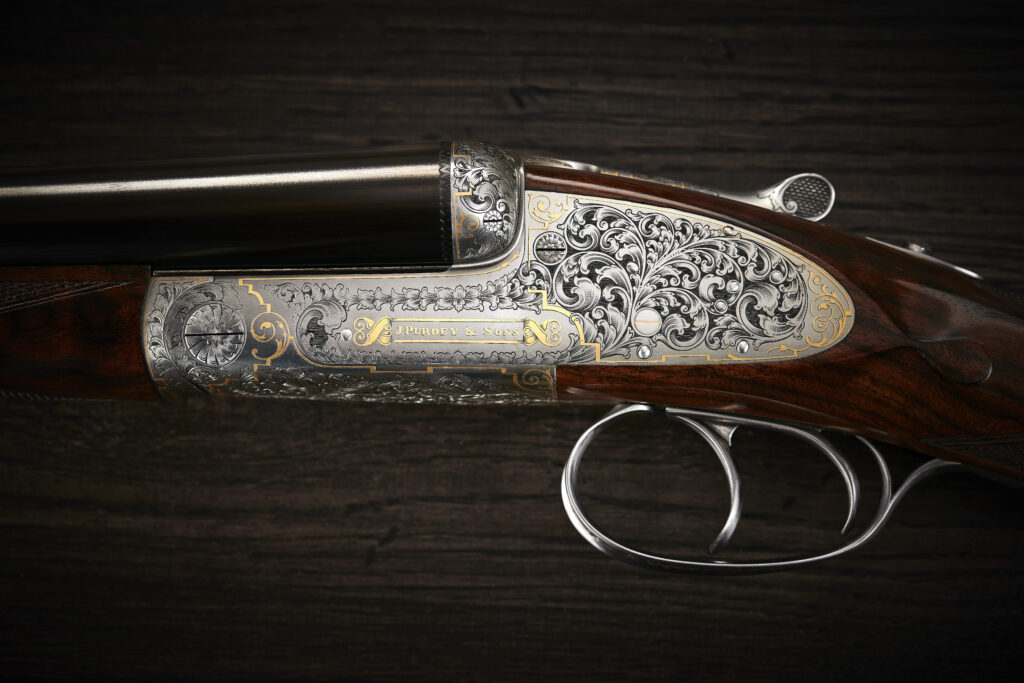

The brand helps, naturally. Purdey may have made shotguns for the great and good since it was founded by James Purdey in 1814, just nine years after completing his own apprenticeship with another gunmaker on Oxford Street — and, under the leadership of his son, also James, it was soon scooping up royal warrants ever since the Prince of Wales (later Edward VII) and Queen Victoria first bestowed theirs, with the likes of Charles Darwin and India’s Maharajas also customers. By the Edwardian era — under James Purdey the first’s great grandson, and when hunting came into its exotic and quixotic own — a Purdey was the de facto gun of choice for anyone with the money and insight. But its rarity has also enhanced its reputation — with the less great and bad too. For all that there are many great gunmakers around the world, not for nothing did London’s post-war criminal underworld, in a kind of back-handed compliment, use Purdey’s name as slang for any shotgun.

And the resonance of the name no doubt also saw it chosen — by actress Joanna Lumley, it’s said — for the kick-ass spy she played in ‘The New Avengers’. “In fact, I am always humbled by how cherished the Purdey name is in the US, for example,” notes Irby, “and the US has its own tremendous gunmakers.” The living history too is alluring. The company has kept a written record of every gun made in what it calls the ‘dimension books,’ with only records for 1814-1816 missing; the ‘Black Book’ believed to been lost through bomb damage but, ever hopeful, perhaps yet to be uncovered behind a cupboard or at the bottom of a trunk. To own a Purdey is literally to be made part of those records. A visit to Audley House is to be bathed in some 130 years worth of memorabilia and momentous moments — such as when General Eisenhower and Churchill met in the building’s Long Room to draw up battle plans during World War Two.